At Candor, our leading philosophy on board manufacturing is based in delivering superior products while constantly looking for new environmentally-friendly initiatives. Our PCB manufacturing and assembly innovations are top of the line, and our board manufacturing process continues to be filtered through both customer standards and our own. We’ve replaced many undesirable products and chemistries from the process that’s found in a majority of PCB shops globally—our assembly innovations go above and beyond the standard.

Streamlined Manufacturing Process

Our simplified, streamlined manufacturing process has become a global standard. We have reduced waste, improved operation time, and eliminated many inconsistencies in our PCB board construction methodology.

- Customer product benefits that govern functional, qualitative, and aesthetic design for mechanical and electrical stability

- Operator-friendly and environmental-friendly processes and technical skills where we reduce, reuse, and recycle

- A process that surpasses restrictions while using less water, with fewer steps, less monitoring, and better ease of use.

- Our process has eliminated formaldehyde, dry-film resists, EDTA, tin-lead resists, by-products, and ammonia-based etch chemistry.

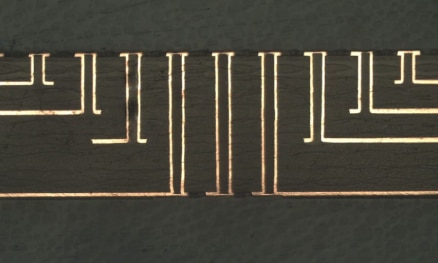

Liquid Organic Liquid Photoresist

Candor is proud to be the only PCB company globally that has perfected the liquid photoresist process. Because of our streamlined innovations, our primary imagining wet process is not subject to any adhesion failures or other defects. This results in greater line control at etching.

- Customer product benefits on all PCB boards that govern functional, qualitative, and aesthetic results.

- Our boards are manufactured with thick and heavy copper, with excellent 2% tolerance matching, landless via capabilities, fine line capabilities, and uniform copper distribution.

- All boards are designed for mechanical and electrical stability and our process has fewer defects.

- Operator-friendly design, with a simplified process that doesn’t rely on dry film-related processes and is environmentally focused

Mechanical Drilling Blind/Buried Vias

By using contact drilling, Candor is able to achieve more precise drilling depths without using a laser, mitigating some of the expenses of the process. Our innovative process controls depth by a combination of linear scale and electrical detection.

- A reduced cost from standard expensive laser processing.

- Overall reduction in field failures, with improved drilling quality.

- More precise than laser drilling without any of the problems associated with laser ablation.

- Better customer satisfaction that saves time and money, and results in a better-controlled drill depth.

Graphite Metalization

Candor’s boards last longer in the field due to our direct graphite metalization process, which provides superior bonds to the inner layer junctions of all PCB boards. Our streamlined and perfected process yields greater performance through thermal cycling, which improves quality and longevity.

- Better customer benefits and values, with increased performance against all destructive testing.

- Easier to operate by reducing complex baths that might require constant measurements and observations.

- Environmentally-friendly design committed to reducing and recycling products without using harmful EDTAs or formaldehyde.

- Less water used overall, surpassing restrictions that make the process superior to electroless copper.

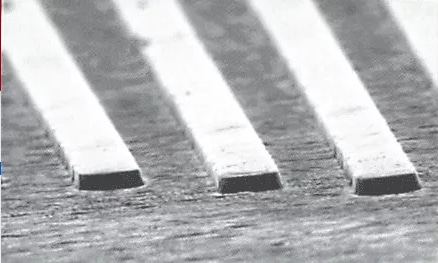

Panel Plating

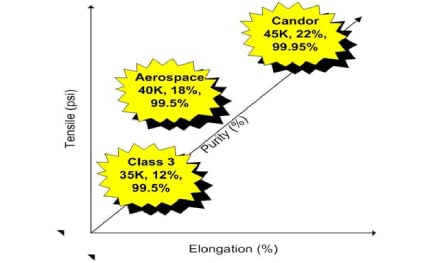

Candor’s streamlined panel plating process improves tensile strength and elongation, meaning your boards will be able to take more heating cycles. Years of manufacturing innovations have allowed our panel plating method to surpass all comparable conventional board builds.

- This process results in a perfect plating thickness of both hole and surface, solving conventional issues with tolerances and tensile strength.

- Extremely accurate line widths, with better mechanical and electrical stability.

- We reduce the process calculations to increase the ease of use.

- Environmentally-friendly design that recycles all excess copper, with a reduced scrap rate that mitigates our material footprint.

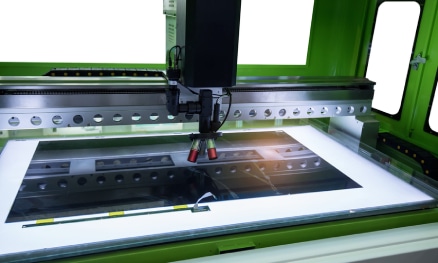

Continuous Foil Lamination

Our continuous copper foil lamination press allows us to laminate multi-layer printed circuit boards, resulting in a product that’s more consistent than any conventional press. Candor’s CCF lamination process uses a continuous roll of foil that’s interlaced between manufacturing panels, acting as a heat resistor that provides consistent thickness that never damages the boards.

- Reduction of bow and twist, with significantly reduced Z-axis variation that improves the product for the customer without relying on significant heat or pressure.

- Improved panel-to-panel constituency that reduces structural deviations and maintains mechanical and electrical stability.

- Process requires no heavy lifting, with computer-controlled heating and cooling system for easier operation.

- Reduced material usage, increased recycling of materials, and fewer power requirements to reduce heating and curing times.

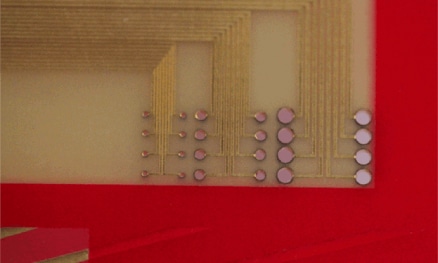

Landless Via

Candor’s exciting new technology allows our design engineers to resolve any space restrictions by eliminating via pad requirements. Where traditional PCB manufacturing required an annular ring to facilitate proper plating, this innovative plating method completely eliminates this requirement in order to give our customers a superior design advantage when dealing with HDI PCB boards. Candor’s positive acting photoresist process is a technology that reduces all spatial constraints. There is no pad required, meaning larger PCB boards are possible.

- Reduces all impedance requirements, with more consistent impedance records and repeatability.

- Significantly improves all HDI spacing issues and reduces tight spacing on boards.

- This process requires no pads, opening up huge possibilities for all clients looking for innovative PCB real estate without sacrificing performance or quality.

- Higher routing density and more traces per layer which reduces the total number of layers required.

Candor’s innovative PCB manufacturing and assembly process speak for itself. If you’re looking for new innovations in PCB board construction, or you have a project that you know can’t be handled anywhere else, give us a call. We provide instant free quotes and always get back to you the same day, and our custom PCB assembly is guaranteed by Candor’s dedication to quality. We are the global leader in all PCB innovations, with lowered costs, reduced processing and delivery time, and better boards. We are driven by our philosophy that innovation begins and ends with customer satisfaction.