Our Process

Our PCB assembly process occurs in four unique stages, where key elements and considerations must be made for single layer, double layer, and multilayer boards. Paste application, automated component placement, soldering, and inspection create your unique PCB, and each stage requires different equipment to ensure your PCB is built correctly, functions as intended, and meets our standards.

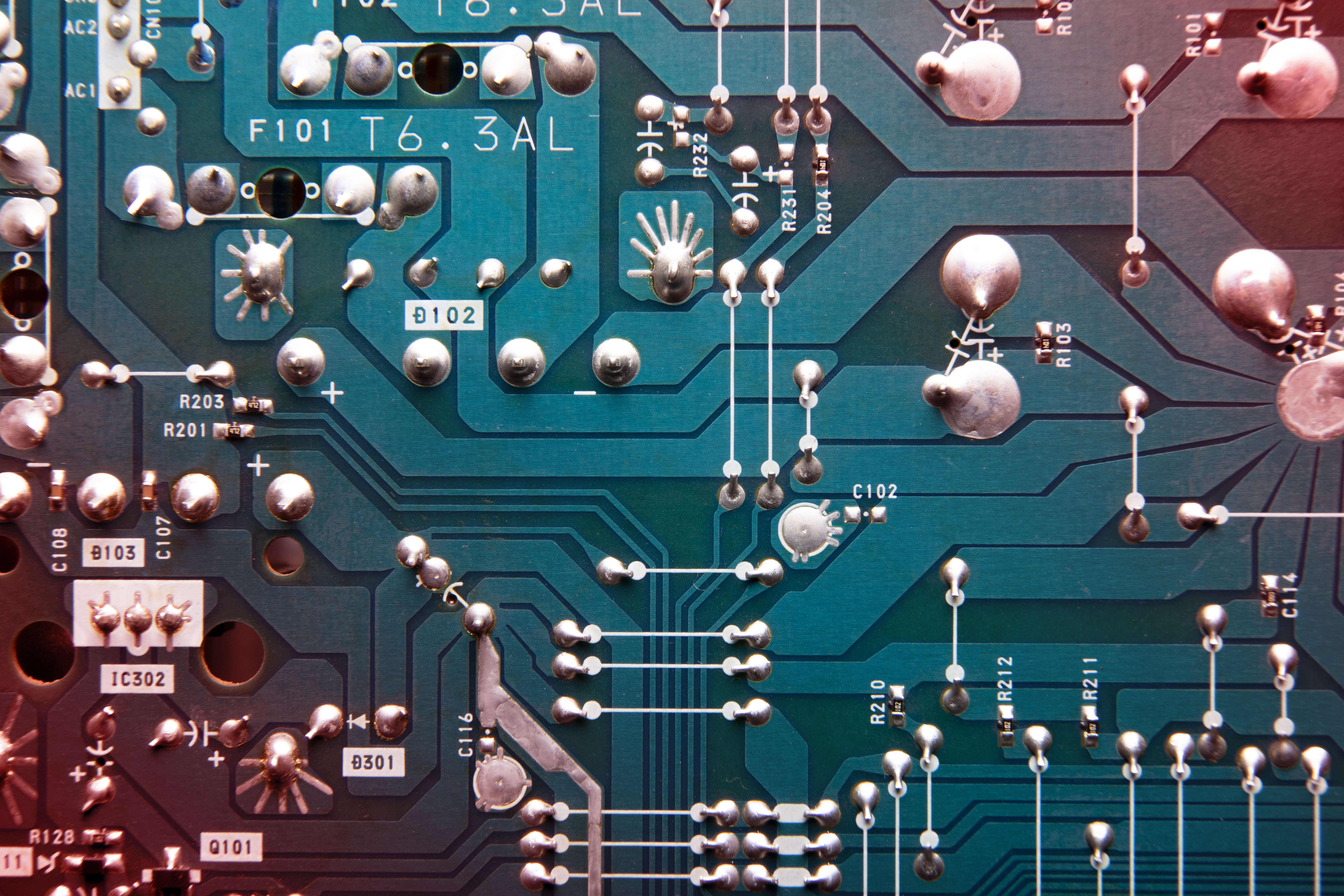

First Stage – Soldering

PCB assembly involves placing various electronic components on the board. The process applies a small amount of solder to the pads on the PCB before placing components. Then, a stencil is used to apply past to the board’s surface. This allows our Automatic Optical Inspection Machine and In-Circuit Test Fixture to make early tests and inspections of your board.

Our solder paste jet printer utilizes extreme precision, eliminating board transfer time whether it’s a single layer PCB or a multilayer PCB. The solder paste allows components to be attached, and an inspection ensures that the paste is evenly applied.

Second Stage – Component Placement

This stage features automated component placement, where a robotic hand accurately positions and mounts the surface-mount components of your PCB. These pieces of PCB use advanced algorithms and vision systems to identify each component’s location and orientation.

By using advanced, cutting-edge techniques, components can be precisely placed on the board. This technique improves the assembly process’s speed, accuracy, and reliability, reduces the need for manual labor, and increases the overall quality of the finished product.

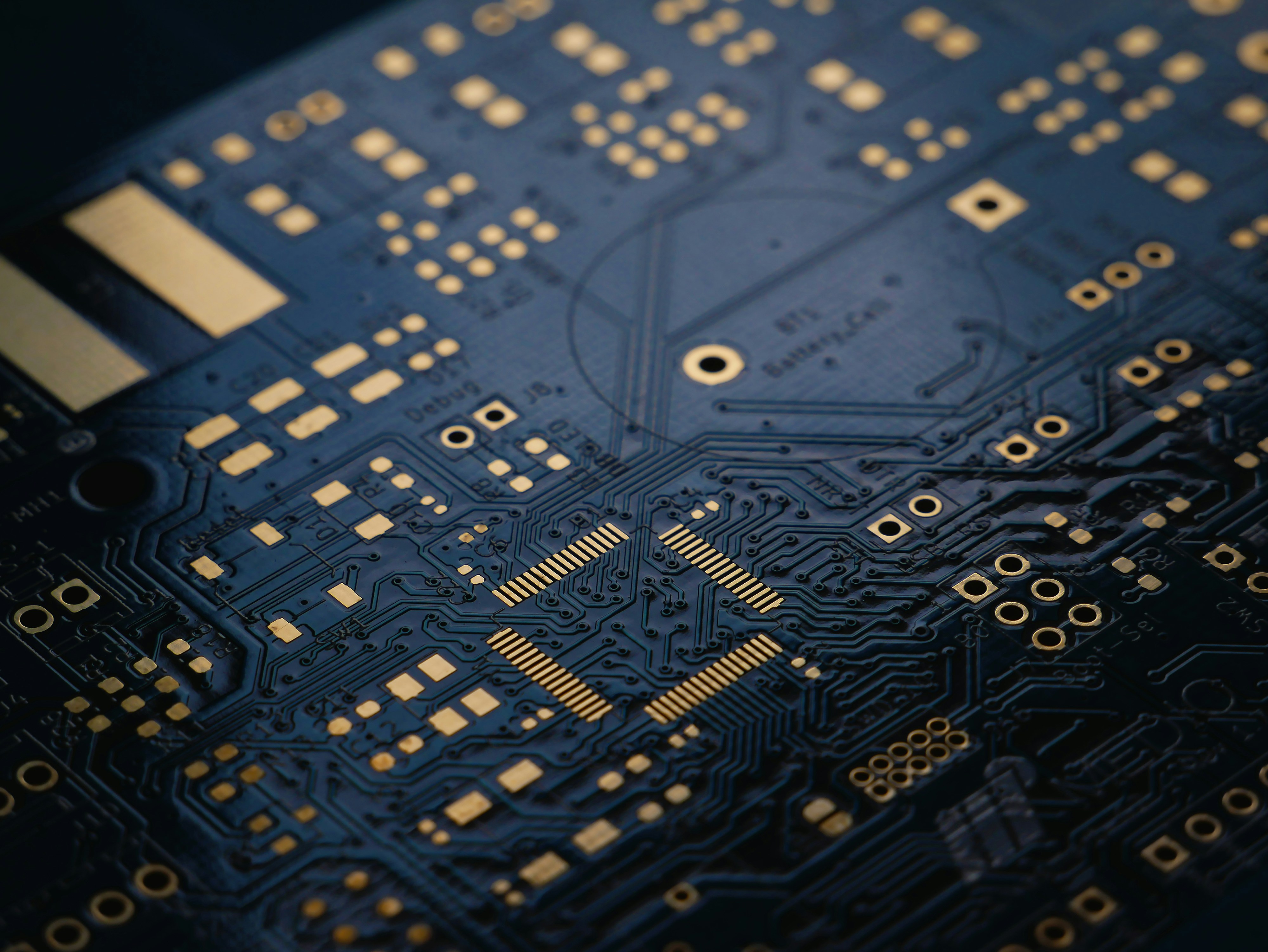

Third Stage – Reflow Soldering

When it’s time for soldering, electronic components and circuit parts on the PCB are conjoined by melting and fusing a metal alloy with a low melting point called a solder. There are other steps, such as adhesives or bindings, that ensure a proper flex adhesive is chosen so that your printed circuit board stays together.

Other epoxy-based laminates are used to assemble your PCB, and Candor utilizes special materials that ensure that boards meet our quality standards. For instance, Black FR4 is a substrate material used for high-performance applications that require excellent electrical and mechanical properties.

Fourth Stage – Quality Control and Inspection

Inspection is the critical final step in Candor’s PCB assembly process. This involves examining the assembled board and ensuring it meets our quality standards. The inspection process helps to identify errors and defects and thwarts other issues that could impact the board’s functionality or reliability. We only deliver excellent, functional, dependable products to our customers.