Advantages of Metal-Backed Copper Boards

Metal core and metal-backed copper boards and PCBs offer benefits beyond traditional circuit boards. Copper provides robust performance improvements, such as higher thermal conductivity, better durability, environmentally friendly solutions, and more.

Copper has the highest level of thermal conductivity, with better heat transfer and dissipation. When copper boards are metal-backed, they can be placed in high-temperature environments where other PCBs would not withstand the heat. Metal-backed copper boards can redirect the heat away from critical circuits, preventing performance issues.

Because copper is recyclable, it’s an environmentally friendly material with drastically reduced waste. Copper core and metal-backed PCBs are less likely to corrode or distort over time, making them the clear option over fiberglass or ceramic boards. They can withstand the manufacturing process better, resulting in reduced breaks and less damage during development.

With a backing of aluminum oxide epoxy, these boards have superior heat transfer ability, making them better suited for electric drives, automotive electronics, LEDs, and other high heat transfer designs. Candor metal-backed boards ensure that your design is getting the heat levels required for superior-quality products.

Applications of Metal Backed Copper Boards

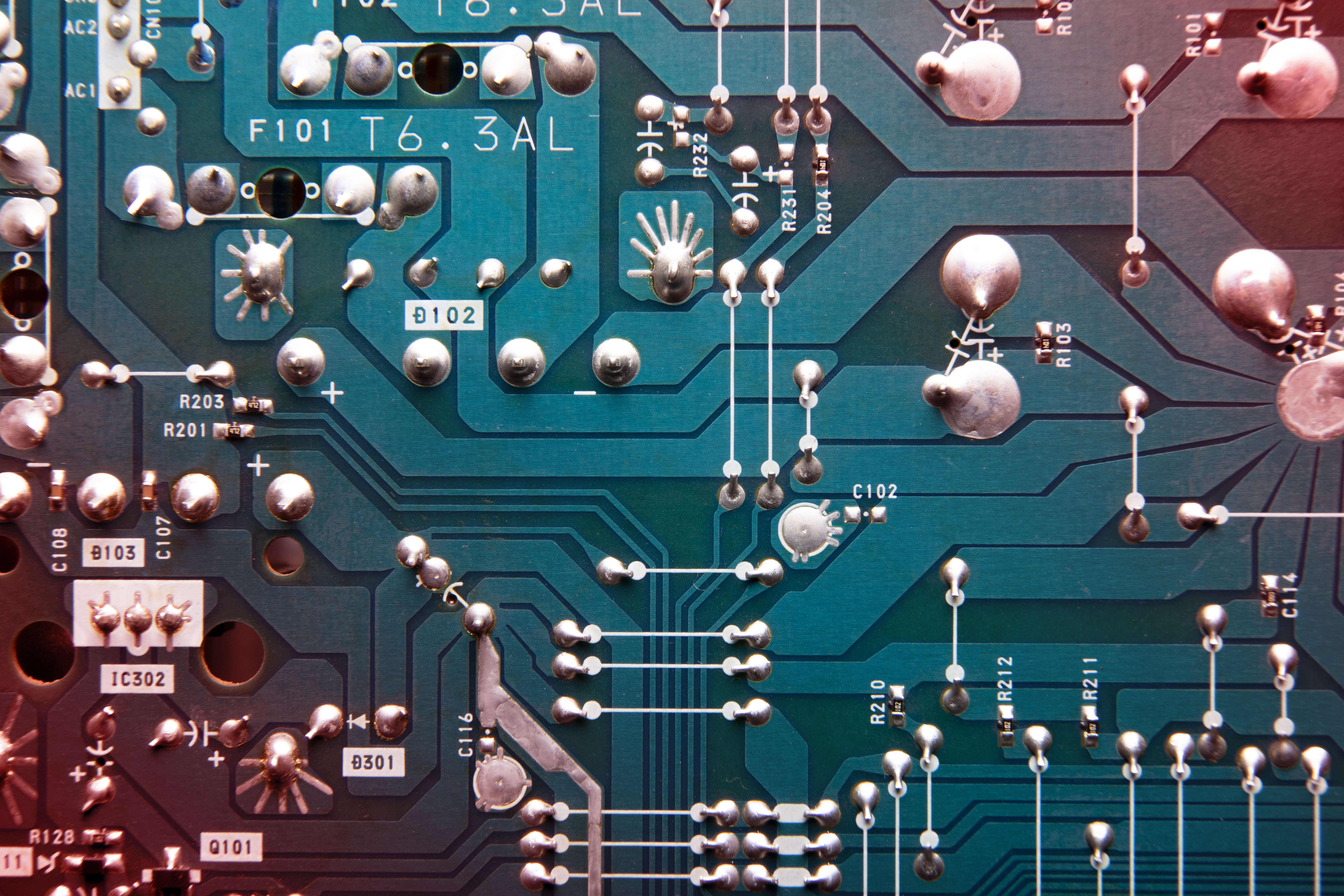

Because of its high thermal conductivity and superior heat dissipation, copper core and metal-backed PCBs are ideal for high-power applications, such as street lights and power supplies. When working with high-temperature products, Candor ensures that your PCB survives severe conditions without damage to critical components by designing boards that offer the best thermal conductivity possible.

Metal core and metal-backed PCBs have significant application advantages, such as:

- Interior lighting, lanterns, and street lights

- Headlights and power controllers

- High-frequency amplifiers and appliances

- CPU boards and power devices

- Bridges, converters, and solid-state relays

- Operating room tools, surgical lighting, and high-powered scanning technologies

Our Solutions for Metal Backed Copper Boards

Candor is the leading supplier of PCBs, copper circuit boards, and other advanced circuit technology. It is important to us that we meet or exceed your expectations and design every board to your strict specifications. If your product requires circuit boards with specific heat tolerances, we can handle any build requirements to deliver the best possible PCB.

Candor provides comprehensive, customized solutions for metal-backed copper boards. There are serious advantages to high thermal conductivity, and specially designed copper core PCBs might be exactly what your device or product needs. By working with the Candor engineering team, you can ensure that your project parameters are met. We run comprehensive design checks, perform exhaustive testing, and provide unparalleled solutions for ease of manufacturability and quick turnaround and delivery. Paired with our environmentally friendly solutions, Candor can ensure the cost-effectiveness, compliance, safety, and optimization you’ve come to expect.