Feb 27, 2024|Technological Advancements and Materials

Navigating the process of ordering a PCB assembly can be complex, but understanding the essential PCB order requirements and steps can simplify it significantly.

This article aims to demystify how to order a PCB assembly, providing clear guidelines and insights into the necessary steps to ensure a seamless and effective PCB ordering experience.

From identifying the type of assembly needed to understanding specific PCB order steps, we cover all the critical elements to make your PCB procurement process smooth and efficient.

Table of Contents

Understanding PCB Assembly

Understanding the different types of PCB assemblies is crucial for making informed choices for your project. Single-sided, double-sided, and multi-layered PCBs serve specific purposes across automotive, aerospace, medical, and telecommunications industries. Knowing these types helps selection meet your project’s needs and ensure correct PCB products.

Types of PCB Assemblies

PCB assemblies come in various forms;

- Rigid-flex printed circuit board

- Mixed assembly

- Through-hole assembly

- BGA assembly

- SMT assembly

Rigid-Flex Printed Circuit Board Assembly

Rigid-flex PCB product assembly is advancing with technologies like integrated ZIF tail and air gap constructions, enhancing design compactness and connectivity. These developments and cost-effective shielded flex layers for EMI and RF shielding make rigid-flex PCBs more versatile and reliable for various industries.

Mixed Assembly

Mixed PCB assembly merges SMT and THT, offering component flexibility suitable for complex, high-density applications. While enhancing functionality and cost-effectiveness, it faces challenges like increased complexity and longer assembly times, instrumental in the medical, industrial, and aerospace sectors.

Through-Hole Assembly

Through-hole assembly, a method for soldering components onto PCBs, ensures strong connections and quality assembly. It involves careful component selection and precise soldering, with Automated Optical Inspection (AOI) ensuring adherence to specifications.

BGA Assembly

BGA Assembly is a method for surface mounting high-density components on PCBs, suitable for high-performance applications. It requires specialized soldering and precise placement, thorough inspections, and potential rework for quality assurance. Understanding its reliability and failure analysis is essential for effective PCB assembly.

SMT Assembly

SMT Assembly, a key method in PCB production, involves soldering components directly onto the board’s surface, offering advantages like smaller sizes, higher density, and faster production. This process usually employs reflow soldering for strong bonding, with inspections ensuring correct placement and solder quality.

Common Uses and Applications

Understanding PCB assemblies’ common uses and applications can help determine your project’s requirements and specifications.

Consumer Electronics

PCB assembly trends include HDI for AI applications, miniaturization for wearables and smart devices, advanced materials for enhanced functionality, and AR/VR tech integration. These developments drive the production of more compact, multifunctional, and efficient electronics, reflecting the evolving consumer demand.

Automotive Components

PCB assembly is increasingly critical for incorporating advanced safety features, efficient power management, and enhanced vehicle connectivity. Trends like miniaturization, high-speed communication, and sustainable manufacturing drive innovation, leading to more intelligent, efficient, and eco-friendly automotive designs.

Medical Devices

The medical PCB assembly industry is evolving with trends like miniaturization, high-density interconnects, and IoT integration, catering to the increasing demand for compact, high-functional medical devices.

These advancements and strict adherence to safety and regulatory standards are shaping PCB designs to be more efficient, reliable, and suitable for diverse medical applications.

LEDs

LED PCB assembly is evolving with trends like miniaturization, advanced heat dissipation materials, and new semiconductor materials, enhancing its applications across various industries.

These advancements in LED technology are leading to more efficient, compact, and versatile lighting solutions that meet diverse energy efficiency and lighting performancerequirements.

Aerospace

Aerospace PCB assembly is crucial for reliable operation in extreme conditions like high radiation, extreme temperatures, and vibrations. These PCBs require materials with low thermal expansion and robust designs to ensure durability and precision.

Advances in technology focus on integrated cores, miniaturization, and corrosion-resistant materials to meet the stringent standards of aerospace applications.

Industrial Equipment

PCB assembly is evolving in industrial equipment, focusing on automation, technological innovation, and sustainability. These advancements enhance production efficiency and accuracy while also considering environmental impacts and the challenges of a globalized supply chain.

Choosing a PCB Assembly Service in 7 Steps

When choosing a PCB assembly service, following an appropriate timeline is important to ensure the timely delivery of your order.

How to Order a PCB Assembly

- Follow an Appropriate Timeline

- Consider Experience

- Evaluate Quality

- Explore Testing Options

- Ask About Customer Support

- Compare Costs

- Look for Red Flags

Follow an Appropriate Timeline

To ensure a smooth and efficient PCB assembly process, it’s crucial to carefully follow an appropriate timeline when choosing a PCB assembly service. Proper planning is paramount to managing factors affecting the PCB assembly timeline.

Consider Experience

When selecting a PCB assembly service, prioritize providers with relevant experience and expertise, ensuring they can handle complex assemblies and offer quality control. Their flexibility and innovation in various industry applications are crucial for delivering high-quality, reliable products.

Evaluate Quality

For high-quality PCB assembly, prioritize services with rigorous quality control, industry-specific experience, and robust technology and equipment. Essential factors include certifications, inspection processes, responsiveness, and cost-effectiveness.

Explore Testing Options

In PCB assembly, testing methods like In-Circuit Testing, Automated Optical Inspection, Flying Probe Test, X-ray inspection, Functional Testing, Burn-In Testing, and Visual Inspection are essential to ensure the boards’ functionality, reliability, and quality.

Ask About Customer Support

Effective customer support in PCB assembly is essential for guidance on test methods, programming solutions, and other concerns, and it often includes turnkey solutions for component sourcing and a seamless ordering process.

Compare Costs

When comparing PCB assembly service costs, consider labor costs, turnaround time, production volume, component types and sizes, testing and inspection requirements, location, certifications, and value-added services.

Look for Red Flags

When choosing a PCB assembly service, be wary of unresponsiveness, lack of relevant experience, questionable quality assurance, insufficient testing services, poor customer support, inflexibility, high staff turnover, lack of transparency, and excessive additional fees.

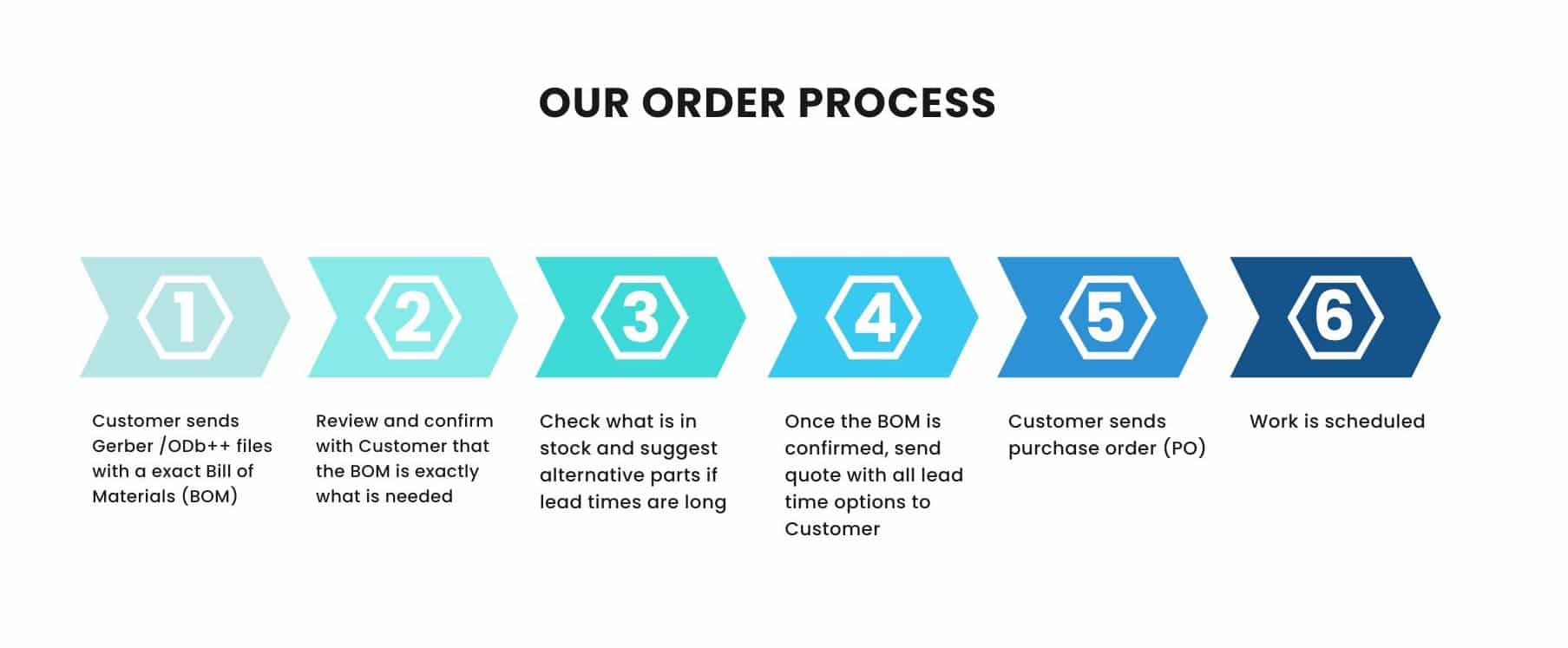

Candor’s Order Process Explained

Candor’s PCB assembly service offers rapid turnaround times, with options for various assembly techniques and materials. Depending on the project, customers can expect quick turn services, ranging from a few hours to days.

Candor’s team handles component procurement and management, offering low-cost turn-key assembly. For specific projects, they provide quotes and require customer approval for major decisions. The fastest turnaround offered by Candor is 24 hours for up to eight layers.

Conclusion

Certainty around how to order a PCB assembly has always been challenging. With a quick turnaround time, affordable prices, and various manufacturing methods and materials, you can find the perfect solution for your project needs.

Simply provide the necessary information and request a quote to get started. Don’t wait any longer, dive in and order your PCB assembly hassle-free today!

- Sunny Patel is the Engineering and Sales Manager at Candor Industries. Sunny is trained as a IPC-A-600 trainer, AS9100 Lead auditor, IPC CID and got his Engineering degree at the University of Toronto.

Latest entries

- February 27, 2024Technological Advancements and MaterialsHow to Order a PCB Assembly

- February 26, 2024Product Innovations and DesignReduce PCB Design Cost

- February 7, 2024Technological Advancements and MaterialsNavigating Low-Cost PCB Assembly

- January 24, 2024Quality and TestingA Guide To Automated Optical Inspection (AOI)