Nov 20, 2023|Product Innovations and Design

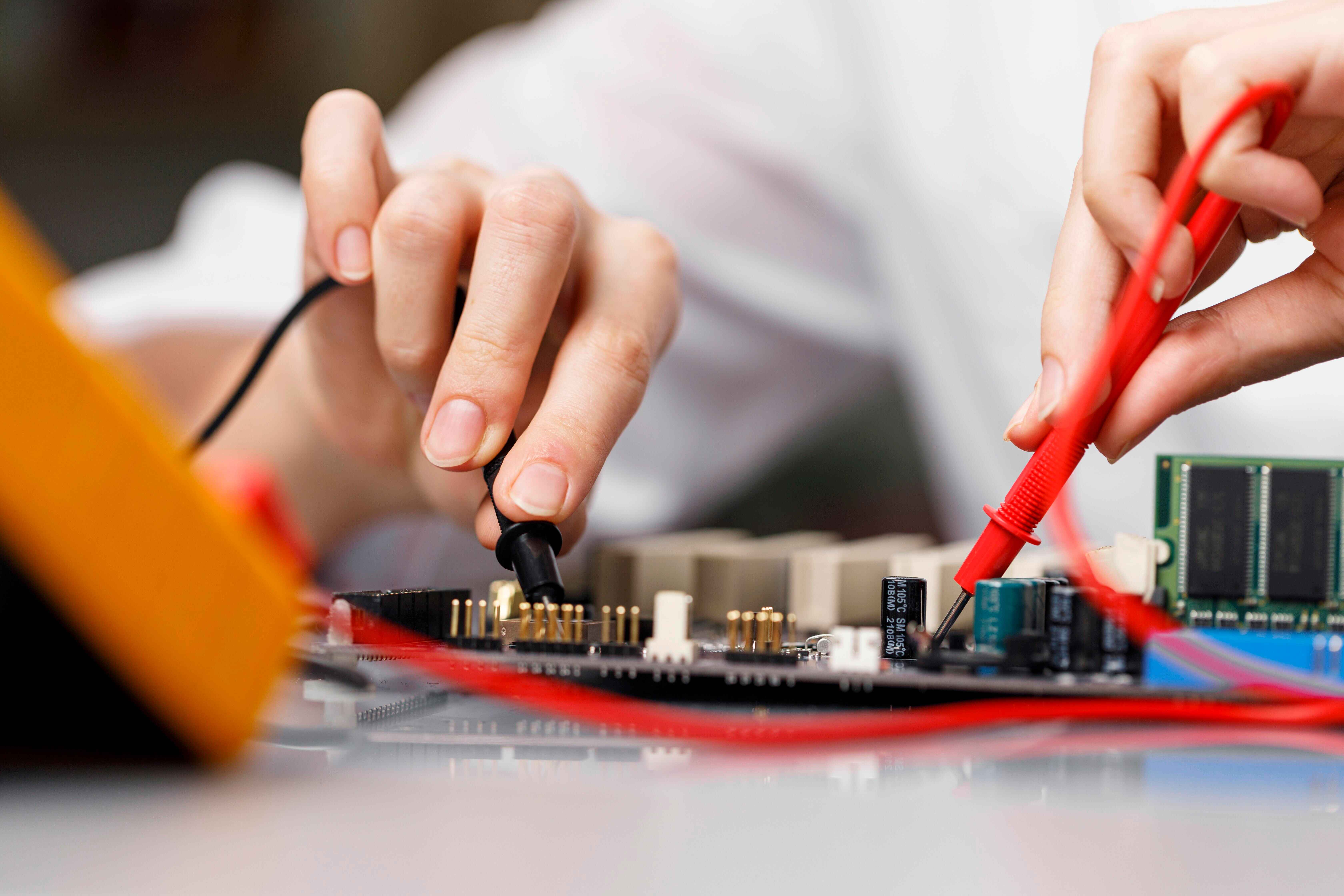

Introducing the transformation from schematics to a Printed Circuit Board (PCB) is pivotal in understanding the intricate process of creating functional electronic devices.

The schematic serves as the blueprint, elucidating every detail that needs to be considered when Designing a PCB.

Table of Contents

- 1 Schematics to PCB: Do You Really Need a Schematic?

- 2 PCB Layout Steps

- 3 Translating Schematic to PCB Layout

- 4 Finalizing and Prototyping

- 5 Conclusion

Schematics to PCB: Do You Really Need a Schematic?

Before delving deeper into the subtleties of PCB creation, one might ponder if a schematic is truly indispensable in the PCB design process.

The schematic is the map guiding every connection, and every component, ensuring the seamless functionality of the resultant PCB Board.

What Is a PCB Schematic?

A PCB Schematic is a graphical representation depicting a specific circuit arrangement’s electrical connections and functions.

It lays the foundation for the subsequent PCB Design Process, offering a visual insight into the circuit’s operation, component interaction, and connectivity.

What Does a PCB Schematic Contain?

The schematic encapsulates extensive details, defining every component, connection, and layout.

It integrates symbols representing various components, interconnected by lines symbolizing the conductive pathways, facilitating an in-depth understanding of the circuit’s workflow and functionalities.

How Is a PCB Schematic Used?

Utilizing the schematic, designers can meticulously structure and refine the layout of the PCB Board, translating the depicted connections and components into a tangible, operational board.

The accurate rendition of every element and connection in the schematic ensures the optimal performance and reliability of the finalized PCB.

By apprehending the crucial role of schematics, we get closer to comprehending the intricate journey from a conceptual design to a fully functioning PCB. The schematic is a mere requirement and vital in achieving precise and efficient PCB outcomes.

PCB Layout Steps

The journey from schematics to a tangible PCB involves a meticulous series of steps, each critical in the design process. Each step is like a building block, ensuring the foundation is solid for the subsequent phase.

-

Step #1: Choose a Board Size

Selecting an appropriate board size is crucial, as it determines the amount of available space to place components and run traces, impacting the overall functionality and efficiency of the PCB.

-

Step #2: Create the Stackup

Forming the stackup involves deciding on the number and arrangement of conductive and insulating layers, crucial for determining the Different Types of PCBs and their applications.

-

Step #3: Arrange Your Components

Strategically placing components is pivotal, considering the connectivity, heat distribution, and accessibility, optimizing the performance and integrity of the board.

-

Step #4: Route the Traces

This step is about designing the pathways connecting the components, maintaining signal integrity, and minimizing interference, which is essential for a reliable PCB.

-

Step #5: Check for Errors

Error-checking is imperative to identify and rectify any mistakes or inconsistencies in the layout before moving to the prototyping stage, averting potential complications and ensuring the quality of the final product.

Translating Schematic to PCB Layout

Transitioning from a schematic to a PCB layout is a nuanced process, necessitating precision and attention to detail, facilitated by sophisticated software tools and techniques.

The Role of Software Tools

Electronic Design Automation (EDA) is pivotal, enabling PCB designers to transform a schematic into a functional PCB through a suite of specialized tools, optimizing the design and prototyping phases. This aids in Picking a PCBA Manufacturer efficiently.

Top 5 PCB Design Software Tools

Navigating through the available tools, five software suites emerge as frontrunners due to their extensive capabilities and user-centric designs.

Altium Designer

It’s renowned for its comprehensive features and user-friendly interface, catering to diverse design needs.

EasyEDA

A cloud-based tool offering convenience and accessibility, ideal for small to medium-sized projects.

Eagle PCB

Eagle is versatile, suitable for various design complexities and scales, providing robust functionality.

Allegro PCB Design Flow

Known for its advanced capabilities, accommodates intricate designs and high-speed requirements.

DesignSpark PCB

It stands out for its intuitive interface and expansive library, beneficial for designers of all levels.

Ensuring Compatibility Between Schematic and PCB Layout

Use a netlist

Employing a netlist ensures that the connections depicted in the schematic are accurately represented in the PCB layout, maintaining design coherence and integrity.

The Importance of Layers in PCB Layout

Understanding the layer structure is vital, influencing the board’s electrical properties, stability, and complexity.

What Are Single-Layer PCBs?

Single-layer PCBs have one conductive layer, suitable for simple electronic applications due to their limited complexity.

What Are Multilayer PCBs?

Multilayer PCBs, with multiple conductive layers, are apt for intricate designs, offering enhanced functionality and PCB Design Software capabilities, fulfilling the needs of advanced electronic devices.

Finalizing and Prototyping

Reaching the end stages of the PCB design process is crucial, and this involves finalizing the design and moving on to the prototyping phase, where the theoretical aspects are translated into tangible products.

Choosing the Right PCB Manufacturer

Selecting an apt PCB manufacturer is pivotal in realizing the design, ensuring that the subsequent production aligns with the envisioned quality and functionality.

Expertise and Manufacturing Capabilities

Considering a manufacturer’s experience and proficiency in handling various design complexities and manufacturing demands is crucial, ensuring the final product aligns with design specifications and quality standards.

Product Certifications

Opting for a manufacturer with relevant certifications ensures adherence to established standards and protocols, guaranteeing the reliability and quality of the final product.

On-Time Delivery

A manufacturer’s ability to meet deadlines is crucial, preventing delays in product launches and ensuring the seamless progression of subsequent processes.

Customer Support

Responsive and knowledgeable customer support is invaluable in addressing queries, resolving issues, and facilitating smooth communication throughout the manufacturing process.

Cost

While cost is a significant consideration, balancing it against quality is essential to avoid compromises that could affect the performance and durability of the end product. Prioritizing value over mere pricing will ensure a more successful and reliable project outcome.

Conclusion

The journey from schematics to PCB involves multiple intricate steps, each requiring attention to detail and precision.

It begins with drafting a meticulous schematic to visualize and plan the circuitry, then converting it into a detailed PCB layout using advanced PCB Design Software.

After the layout phase, selecting the right manufacturer is critical, considering their expertise, certifications, and customer service quality.

Each stage, from initial design to final prototyping, ensures the resultant PCB aligns perfectly with the envisioned functionality, quality, and reliability.

- Sunny Patel is the Engineering and Sales Manager at Candor Industries. Sunny is trained as a IPC-A-600 trainer, AS9100 Lead auditor, IPC CID and got his Engineering degree at the University of Toronto.

Latest entries

- February 27, 2024Technological Advancements and MaterialsHow to Order a PCB Assembly

- February 26, 2024Product Innovations and DesignReduce PCB Design Cost

- February 7, 2024Technological Advancements and MaterialsNavigating Low-Cost PCB Assembly

- January 24, 2024Quality and TestingA Guide To Automated Optical Inspection (AOI)