Jul 5, 2022|Product Innovations and Design

A reference designator or Ref Des (REFDES) helps to identify a component within an electrical schematic or on a PCB. Many designators exist out there, and they are all equally important in making the PCB an easy and effective piece of technology for designers. Read on to discover more!

Table of Contents

What Is A Reference Designator in PCB?

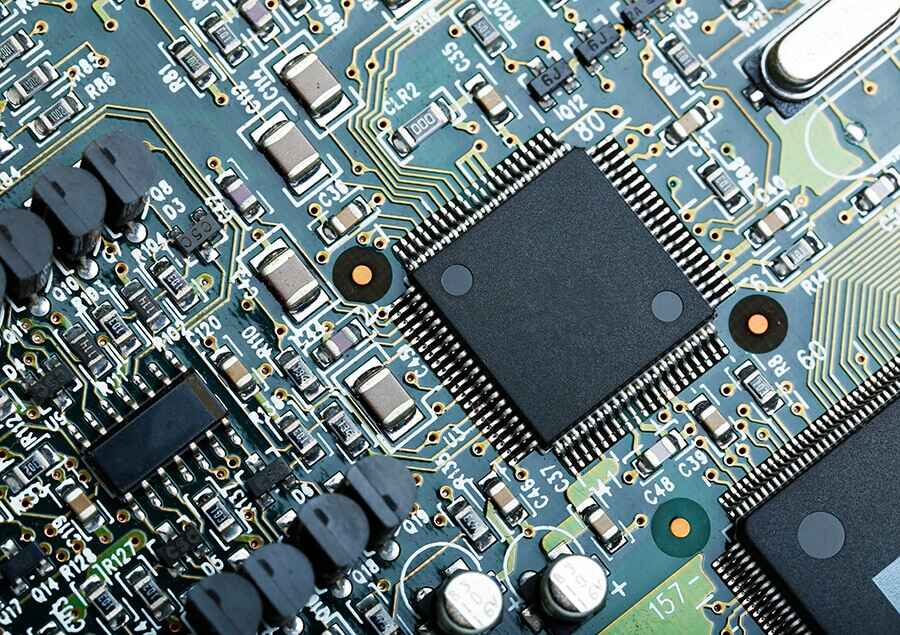

Reference Designators help manufacturers identify specific components of the PCB or Printed Circuit board. PCBs are everywhere, found in all of your electronics.

Many little parts build up a PCB, so it’s important to label them all with “designators.” Labeling them is crucial to making the developmental process of the PCBs as efficient as possible.

Designators are what set the different components of the PCB apart. With designators, it is easier for manufacturers to keep track of all the parts the PCB board needs. Designators also assist during troubleshooting because when a piece malfunctions, it can be identified and replaced.

There are quite a few different designators. One such version utilizes abbreviations and numbers. For example, B will stand for battery. Numbers will come into play if and when there is more than one of each component, so it could be labeled as B13 if it is the thirteenth battery that is within the switchboard.

Fiducial marks are important during assembly to ensure the PCB placement is precise. Polarity indicators are also extremely helpful in displaying the voltage direction, which must be easily accessible for PCB designers and manufacturers.

Reference designators are printed on the circuit board, next to the component it’s referencing. While PCBs will differ in features, these are the typical features included, along with the usual identifying letter:

- Battery — B

- Circuit Breaker — CB

- Cable — wire W

- Operational Amplifier — OP

- Plug — P

- Inductor — L

- Diode — D

- Switches — S or SW

- Resistors — R

- Capacitors — C

Reference Designators help PCB designers keep track of the components they need for their board for the BOM (bill of materials). Reference Designators also identify troublesome pieces that need replacement either during or after manufacturing.

How To Use a Reference Designator?

You can use a reference designator by carefully studying your PCB. While there are seemingly millions of little things on your PCB, there are also handy reference designator standards, which are numbers and letters silkscreen printed in white.

There are other markers for fiducial marks that help align the board during assembly. Pin 1 indicators help specify the first pin for ICs to ensure correct orientation and connections.

By understanding what each reference is for, you can understand how to use it. It is vital that the reference designators indicate the correct part, otherwise they’ll run into trouble down the assembly line.

PCB Reference Designators You Should Know

The PCB reference designators you should know are the ones you’ll run into the most. Though PCBs are undeniably different from each electronic that they’re in, there are a few common components you can expect in every single board so it’s best to have those memorized to quickly move onto the newer features.

By recognizing the basics, you’ll have a general understanding from board to board. The board can then be customized with its separate unique features while being able to remain a comprehensible board.

Beyond recognizing the fiducial markers and knowing where the polarity and pin 1 indicator are, manufacturers need to memorize the unit number method, where components are assigned a letter and number.

While the number will change depending on each project (you’re not always going to need ten batteries), memorizing each alphabetical indicator for each standard component is a strong start.

If the problem is related to one of the standard features, manufacturers will be able to identify it. And if not, they can easily eliminate the standards and move on to other components.

It makes designing and manufacturing a bit easier because you already have your bill of standard materials in place and can keep going from there. The ASME Y14.44-2008 is a great resource to familiarize yourself with other codes.

Why Are Reference Designators Important?

Reference Designators are important because they make navigating the PCB an easier experience. PCBs are complex pieces of technology, containing many features all squeezed onto one board. It can be a little tricky to know what you’re looking at without the reference designators to guide you.

With the little labels and the codes, tackling problems with your PCB takes less time because you don’t have to bother with learning where everything is. The designators are there to guide you so there’s less struggle between identifying the problem spot and fixing it.

PCB reference designators are also essential because they make it easier to replicate the PCB; because PCBs have such a heavy presence in the technological world, they need to easily be produced since we depend on them so heavily.

Reference designators also assist in BOM, Bill of Materials. A bill of materials helps manufacturers keep track of the parts they need and how many they need. Each BOM should reflect the correct output of energy expected by the PCB board or intended by the designer.

If your Bill of Materials is inaccurate, you’re bound to run into problems with the circuit later.

Conclusion

Every manufacturer should know these standard PCB reference designators because they’ll make all interactions with your PCB, whether at the beginning of manufacturing stages or during troubleshooting, as painless as possible. These references are also universal, making every PCB board somewhat accessible to you.

Since PCBs are different, it’s worth memorizing the standard reference designators you know will appear on all PCBs, from board to board. With that head start, you’ll feel more confident to work on larger boards containing more elements.

Memorizing as many standard reference designators as possible makes life easier when it comes to repairing and creating standard PCBs. Manufacturers can also tackle larger projects with ease down the line since they come fully educated on the basics.

- Sunny Patel is the Engineering and Sales Manager at Candor Industries. Sunny is trained as a IPC-A-600 trainer, AS9100 Lead auditor, IPC CID and got his Engineering degree at the University of Toronto.

Latest entries

- February 27, 2024Technological Advancements and MaterialsHow to Order a PCB Assembly

- February 26, 2024Product Innovations and DesignReduce PCB Design Cost

- February 7, 2024Technological Advancements and MaterialsNavigating Low-Cost PCB Assembly

- January 24, 2024Quality and TestingA Guide To Automated Optical Inspection (AOI)